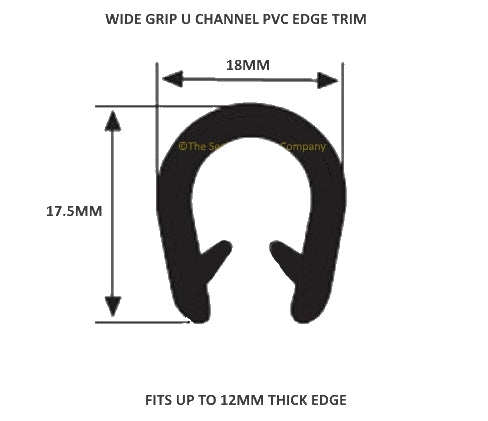

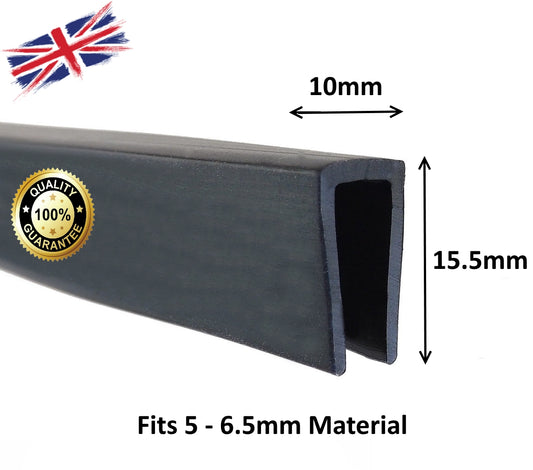

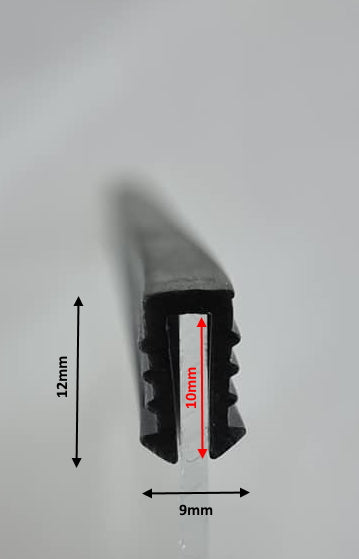

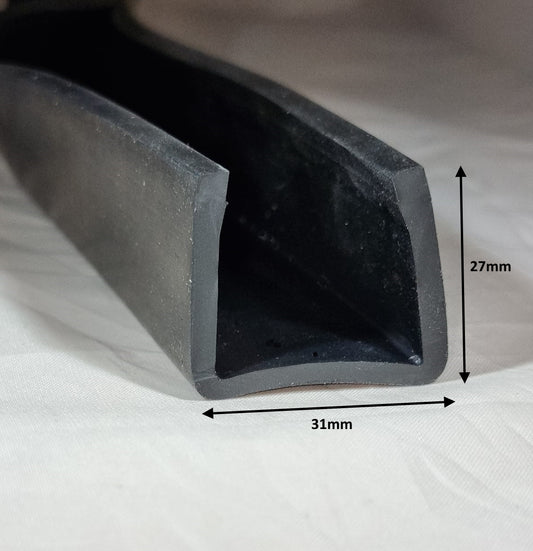

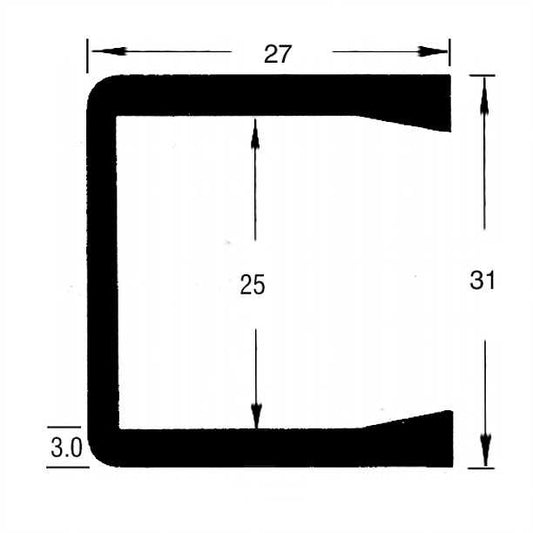

Collezione: Square Channel Rubber

We supply a wide range of Rubber Square Edge Channel for many different applications including protecting sharp edges on doors, glass, panels and metal & wood edging. These can be bonded in place or some have metal inserts.

All our trims are also available as bulk coils in 25, 30, 50 & 100mtr coils depending on coil lengths and we also off a 10% discount on orders over £50 on trim. Listed are our standard off the shelf trims, we also supply another 20+ variants so if you need something not listed here just ask as we may well have stock on the shelf or at the factory.

EPDM is compatible with polar substances, e.g. fireproof hydraulic fluids, ketones, hot and cold water, and alkalis. They are incompatible with most hydrocarbonx, such as oils, kerosene, aromatic, gasoline, as well halogenated solvents.

EPDM exhibit outstanding resistance to heat, ozone, steam and weather. It is an electrical insulator. Typical properties of EPDM vulcanizates are given below.

EPDM can be compounded to meet specific properties to a limit, depending first on the EPDM polymers available, then the processing and curing method(s) employed.

EPDMs are available in a range of molecular weights (indicated in terms of Mooney viscosity ML(1+4) at 125 °C), varying levels of ethylene, third monomer, and oil content.