-

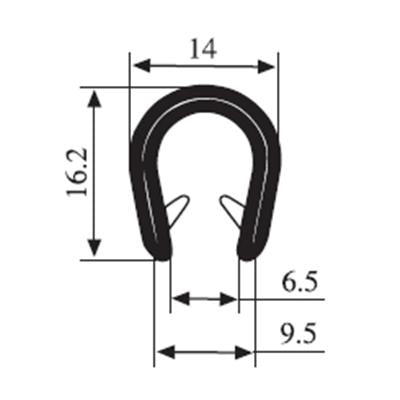

TSEC 011 Self-Adhesive Neoprene 'Eared' Rubber 'D' Section - Durable and Flexible Seal

Prix habituel Du £4.95 GBPPrix habituelPrix unitaire par -

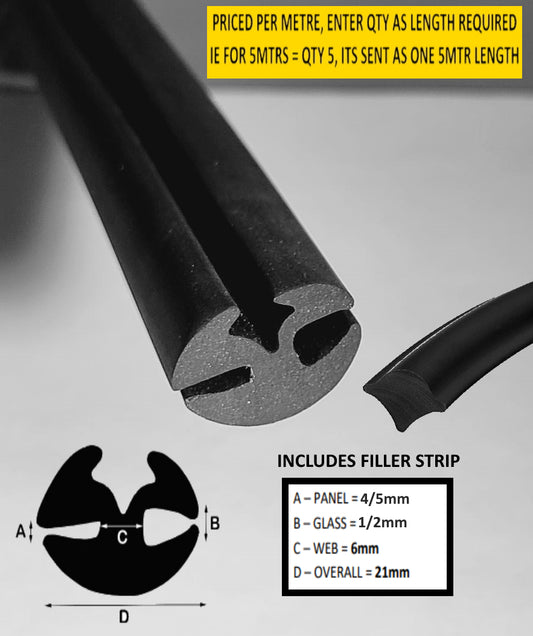

Claytonrite EPDM Glazing Seals

Prix habituel Du £1.99 GBPPrix habituelPrix unitaire par -

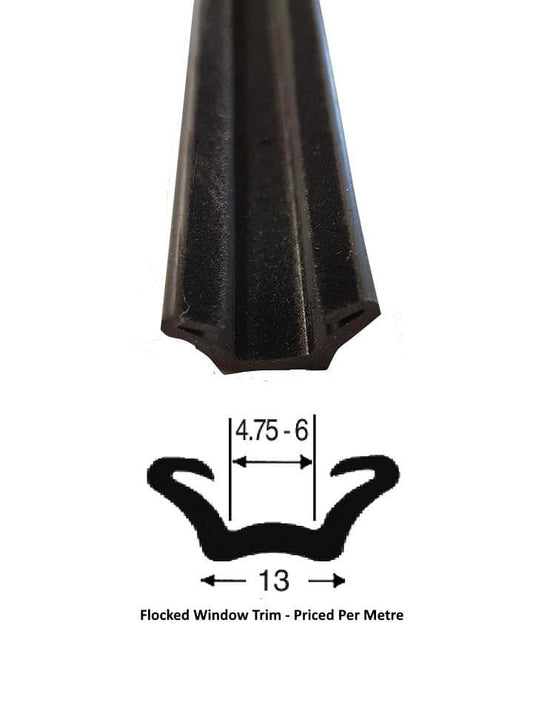

EPDM Flocked Lined Rubber Sliding Window Channel - Durable and Weather-Resistant

Prix habituel £4.75 GBPPrix habituelPrix unitaire par -

TSEC 1400 Small PVC Edge Trim - Durable and Versatile Edge Protection

Prix habituel Du £2.49 GBPPrix habituelPrix unitaire par -

EPDM Sponge D Self Adhesive Hollow Foam Rubber Seal

Prix habituel Du £3.67 GBPPrix habituelPrix unitaire par -

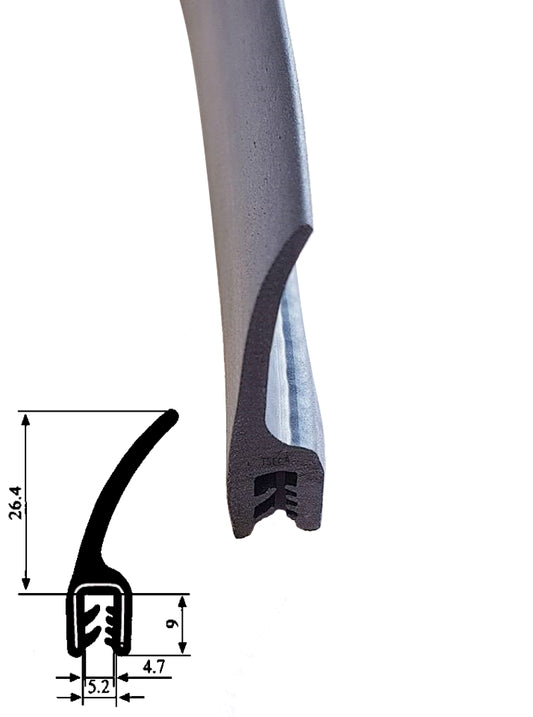

TSEC4800 High-Quality Rubber Seal – Versatile Weatherstripping

Prix habituel Du £5.25 GBPPrix habituelPrix unitaire par -

Neoprene / EPDM Self Adhesive Sponge 1" x 1" (25mm x 25mm)

Prix habituel Du £20.00 GBPPrix habituelPrix unitaire par -

TSEC 3700 Flexible Car protective Rubber Edging Edge Trim

Prix habituel Du £3.75 GBPPrix habituelPrix unitaire par -

SRD BLACK MARINE GRADE RUBBER DOUBLE D FENDER, PER METRE, NARROW BOAT, TRUCK

Prix habituel Du £11.00 GBPPrix habituelPrix unitaire par -

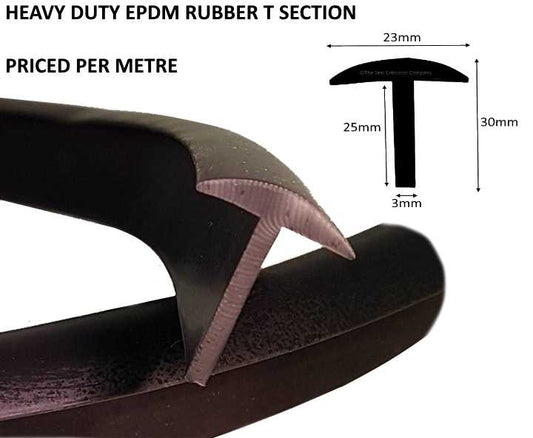

TSEC 1566 'T' Shaped Rubber Section

Prix habituel Du £4.99 GBPPrix habituelPrix unitaire par -

TSEC 1490 Micro Trim - BLACK EPDM SQUARE U CHANNEL EDGE TRIM

Prix habituel Du £3.00 GBPPrix habituelPrix unitaire par -

TSEC 2192 Small Vertical Leaf Fin Rubber Edge Trim - Durable and Flexible Edge Protection

Prix habituel Du £3.80 GBPPrix habituelPrix unitaire par -

EPDM sponge Double D profile Self adhesive hollow foam rubber seal / gasket

Prix habituel Du £8.00 GBPPrix habituelPrix unitaire par -

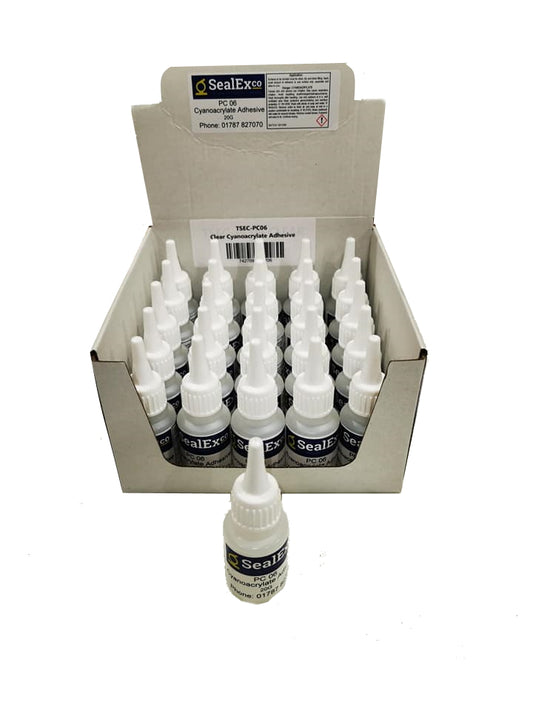

Rubber Extrusion Adhesive - Cyanoacrylate - Seals - Trims - Rubber Bonding Agent

Prix habituel £9.22 GBPPrix habituelPrix unitaire par -

TSEC 2375 Side Fin Seal (Smaller)

Prix habituel Du £4.60 GBPPrix habituelPrix unitaire par -

Closed Cell Neoprene Strips 60mm x 30mm x 2mtr (Plain backed)

Prix habituel £16.75 GBPPrix habituelPrix unitaire par -

TSEC 2185 Small Finned Top Seal

Prix habituel Du £3.10 GBPPrix habituelPrix unitaire par -

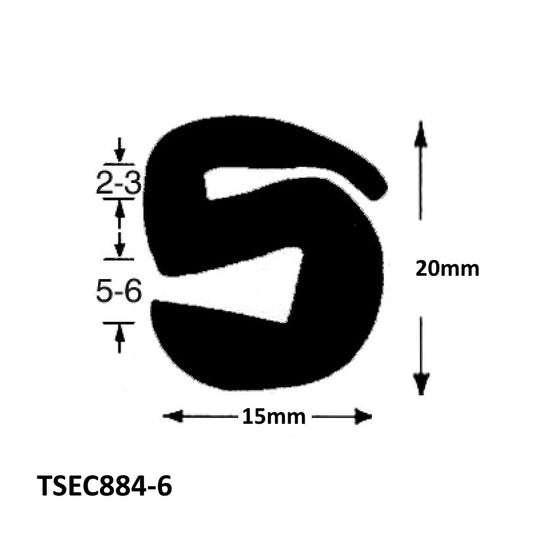

TSEC 884.6 EPDM S-Shaped Rubber Section Glazing Seal - Durable and Weather-Resistant

Prix habituel £6.25 GBPPrix habituelPrix unitaire par -

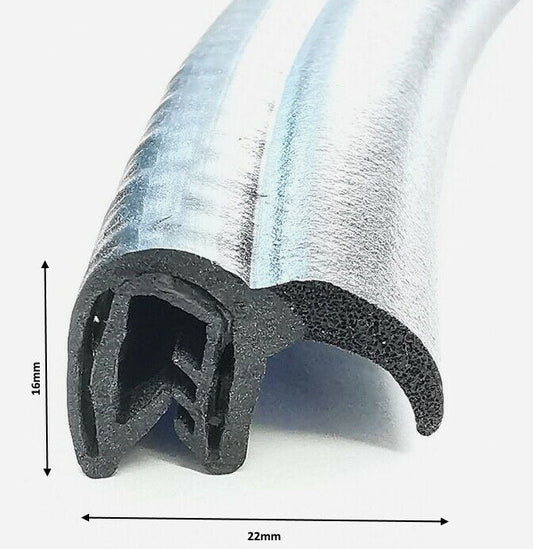

TSEC 2193 Black Rubber Boot Seal - 22mm x 11mm - Grips - 1mm to 3mm

Prix habituel £3.95 GBPPrix habituelPrix unitaire par -

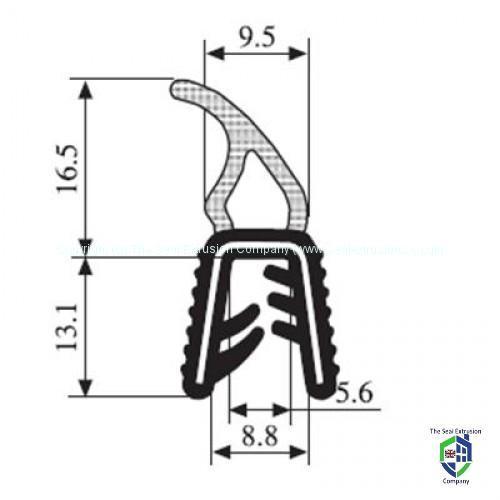

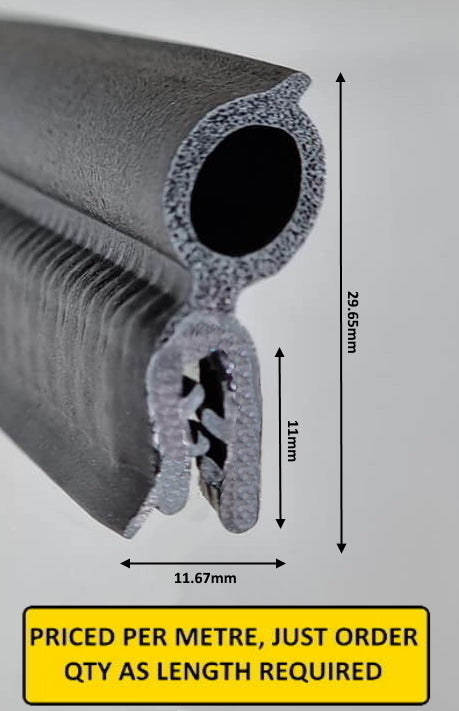

TSEC 567 P Seal / Bead Seal

Prix habituel Du £5.36 GBPPrix habituelPrix unitaire par